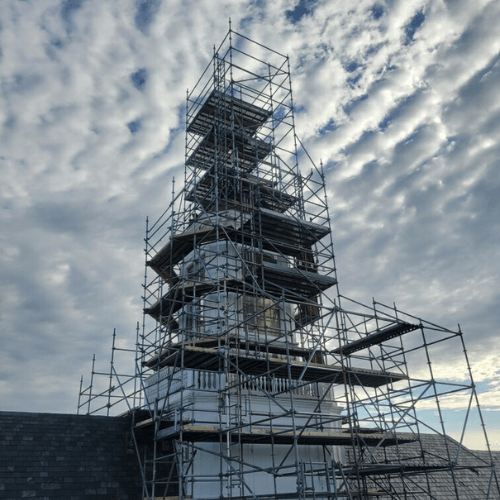

AT-PAC SUPPLIES RINGLOCK FOR STEEPLE REPAIR ON THE HISTORIC DON LOVE MEMORIAL LIBRARY

AT-PAC supplied their client a modular Ringlock scaffold system as a temporary structure for the steeple repair and maintenance at the Don Love Memorial Library in Lincoln, Nebraska. The scaffold solution designed and supplied for the steeple repair required system connections to an ‘as built’ structure for access.

Customer Challenges:

Our client was limited by restrictions on the foot traffic and access to the building, its' lower balcony, and roof. The historical landmark and steeple structure boasts fine external design elements that are impossible to replicable, if damaged. The temporary work platform had to be lightweight, functional, and provide the field crew optimal space to complete the work. AT-PAC design and engineering team had to implement quick turnarounds on both their drawing modifications and corresponding calculations to the city and building's owners for approval.

Solution: AT-PAC’s Design and Engineering Team used their industry knowledge and vast field experience to design a scaffold structure that was efficient and easy to install, using the existing material stocked in their (hire) rental fleet. AT-PAC's Modular Ringlock systems adaptability for use around circular structures and high strength components was the perfect fit for this local landmark. AT-PAC's skilled Design & Engineering team utilizes the latest 3D modelling techniques, QR codes for infield design view and provide traditional 2d plot plan. Safety and erectability is at the forefront of AT-PAC's Design process.

Impact: The ability of AT-PAC to quickly assess and adapt to any situation, such as to handle the Don Love Memorial Library's tall steeple with as-built scaffolding already in place, was fundamental for their client to complete the restoration and repairs with ease, allowing visitors to enjoy for many years to come.

For scaffolding, sales, rentals, and general information, please

reach out to our team!

You might also like

AT-PAC Blog