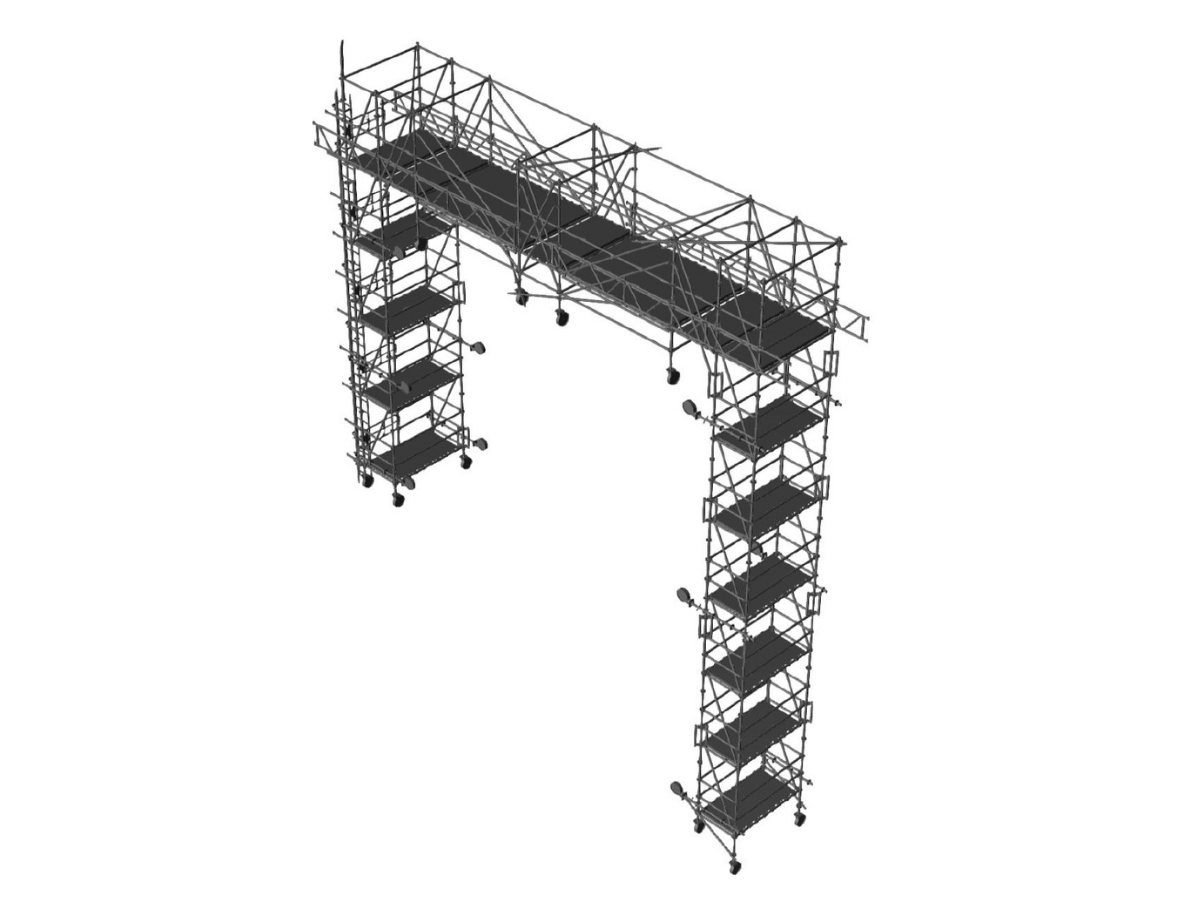

Industrial Craneable Scaffold

Project Type:

Industrial | Power

Project Location:

USA

Project Summary:

Client requested 360-degree access to a circular concrete containment shield roof wall to remove formwork, and finish concrete at 330ft above ground level.

Customer Challenges:

The major challenge for the customer was mitigating working at height. Access to the site crane to get materials to the workface was limited, as was space to store materials for the installation at the working elevation. Schedule constraints meant the scaffold had to be installed in a week.

AT-PAC Solution:

Working closely with our customers Scaffold SME, AT-PAC’s experienced scaffold designers created a crane-able, rolling scaffold solution that allowed our customer to relocate the scaffold by hand 360-degrees around a containment shield roof. The scaffold was erected on the ground and lifted by crane into its working location. Once in location, compression ties utilizing casters installed horizontally against the concrete walls were installed to stabilize the scaffold from perpendicular & parallel movement. A cable to the center of the tank was installed as a secondary support to prevent movement as well as the caster wheel locks engaged when the scaffold was being used.

Impact:

Minimized work at height by erecting the scaffold at ground level and craning the scaffold into place. Reduction of crane use to one lift was required to install the scaffold. This design reduced the required amount of material from 200 tonnes to 5 tonnes, and 8000 labor hours down to 300 hours, equating to a saving of $550,000 compared to traditional fully wrapped containment solution.

For stage scaffolding rentals, please

contact

one of our friendly consultants for more information.