Scaffolding Parts and Accessories | Maintenance | AT-PAC

- Confirm that all scaffolding components are in place and secure: Wedges, bolts, nuts, spigots… even the smallest component must be present and secure to ensure safety.

- Look for cracks, dents and splits in steel or wooden panels: The floor panels of your scaffolding must bear a lot of weight and withstand heavy objects dropped from above. Even a small weakness in one of these surfaces can spell trouble as these heavy forces are exerted during the job.

- Look for sharp edges: Steel and aluminum often develop burrs and lips, which can lead to cuts and scratches not uncommon to heavy construction work. Noticing and fixing sharp edges is a good step toward preventing infections, bumps, bruises, and even avoiding more serious issues like hospitalization.

- Look for any deflection or bends in equipment (due to overloading): This is especially important at weight-bearing supports and flooring panels that have taken on especially heavy loads. If the metal is already bending under the strain, continued traffic and jarring makes it only a matter of when — not if — it will break.

- Check to ensure nuts on clamps and braces move freely: All scaffolding parts and accessories that are intended to move or be adjustable must be properly lubricated and routinely worked to keep them fully functional. Proper maintenance improves safety and avoids slowdowns during the job.

- Replace all missing/removed spigots with the correct bolt and lock nut: There is no room for cob-jobbing or making do with subpar replacement parts when your workers’ health and safety are on the line. Invest in manufacturer-approved replacement parts only.

- Ensure swing gate springs are functioning: Again, this is a seemingly small and simple maintenance item, but it adds another level of safety at every point in the scaffolding design where a safety barrier exists.

You might also like

AT-PAC Blog

Navigation

Global Support Office

Atlantic Pacific Equipment LLC

1455 Old Alabama Road Ste. 100

Roswell, GA 30076 USA

AT-PAC Global Regions

-

North America

Houston (North America Main Office)

11821 East Freeway

Suite 550

Houston, Texas 77029

Atlanta, Georgia (Southeastern Branch Office)

1356 Cobb Industrial Dr

Marietta, Georgia 30066

Baton Rouge, Louisiana (Gulf Coast Branch Office)

2179 Commercial Drive

Port Allen, Louisiana 70767

Columbus, Ohio (Midwestern & Northeastern Branch Office)

2565 Harding Hwy E

Marion, Ohio 43302

Denver, Colorado (Mountain West Branch Office)

8780 E 93rd Pl

Henderson, Colorado 80640

720.736.4625

La Porte, Texas (Southwestern Branch Office)

1606 Sens Road

La Porte, Texas 77571

Los Angeles, California (West Coast Branch Office)

22990 Temescal Canyon Road

Corona, California 92883

Edmonton, Alberta (Canada Main Office)

6215 82nd Avenue

Edmonton, Alberta T6B 0E8

-

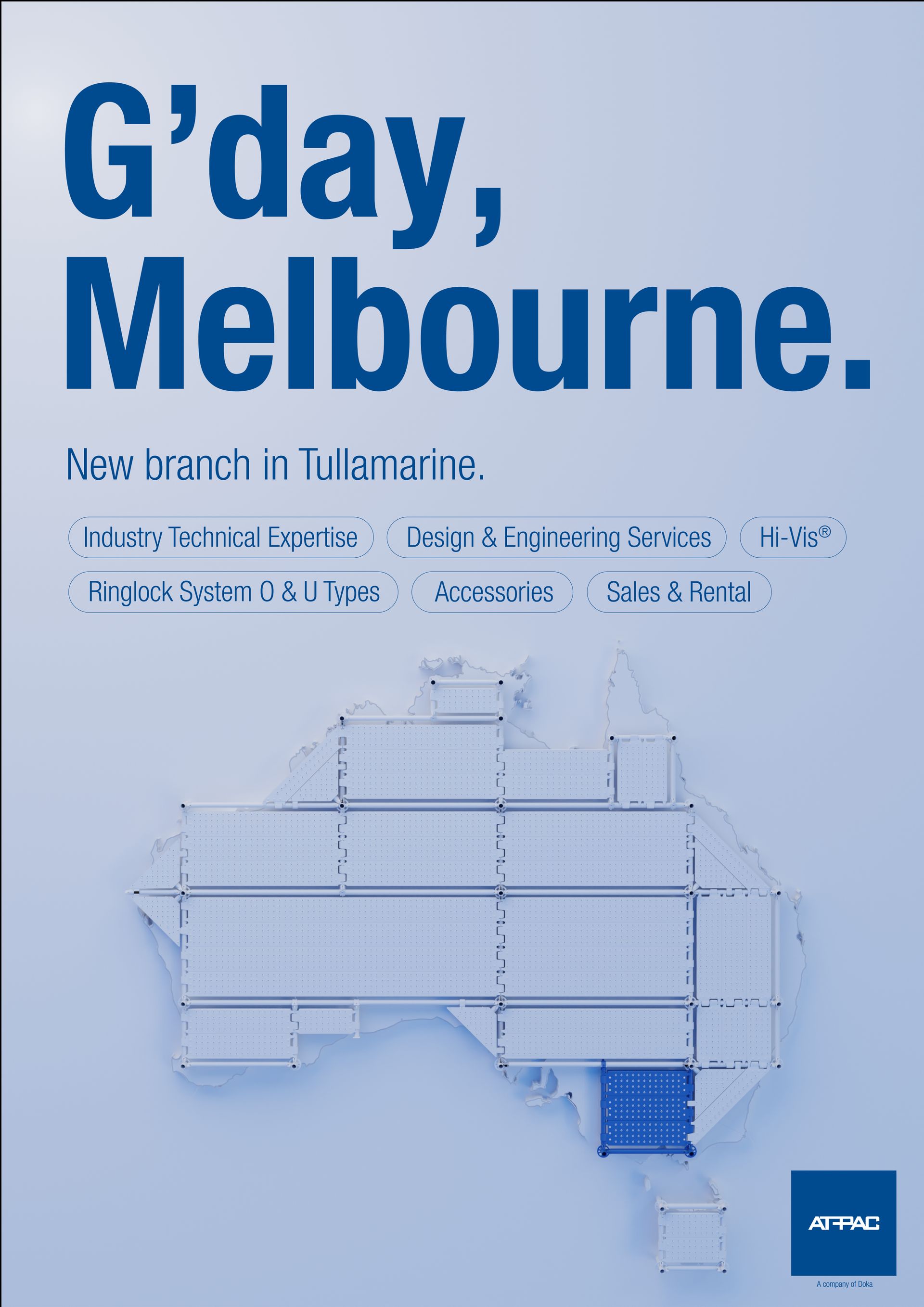

Australia

56 Windsor Road

Wangara, WA 6065

153 Rossmann’s Road

Stapylton, Queensland 4207

21 Gladstone-Benaraby Rd,

Gladstone, Queensland 4680

11 Huntingwood Dr,

Huntingwood NSW 2148

85 Sharps Road,

Tullamarine, Victoria 3043

+61 497 960 608

-

United Kingdom & Europe

Mossburn Avenue, Harthill

Lanarkshire, ML75NF

Unit 19, Park Rose Industrial Estate

Middlemore Road, Smethwick

West Bromwich

B66 2DZ

Europe

Gildestraat 14

6883 DB Velp,

The Netherlands

-

South America

Santiago, Chile (South America Main Office)

Avda. Miraflores 9700

Pudahuel, Santiago

Avda. Pedro Aguirre Cerda 14200,

Antofagasta, Chile

+56.55.2552762

Santa Cruz de la Sierra, Bolivia

Complejo Industrial Del Norte, Lote 35

Km 23, Carretera Warnes

Santa Cruz De La Sierra, Bolivia

Ventas Oriente +591.77270270, +591.75742858

Ventas Occidente/Centro +591.77312652

-

Asia

DISCLAIMER: The information contained in this website is provided by Atlantic Pacific Equipment, LLC (“AT-PAC”) and is for general information purposes only.

Disclaimer |

Terms |

Privacy

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved