Blog Layout

3 WAYS TO IMPROVE SCAFFOLDING SAFETY AT A JOB SITE

June 28, 2019

According to the Occupational Safety and Health Administration (OSHA), more than 2.3 million construction workers

— or 65 percent of the industry — work on scaffolds. It is a dangerous job: 4,500 scaffold-related injuries and 60 scaffold-related deaths hit job sites in the U.S. each year. That adds up to $90 million in lost work days.

As a site manager, one of your main priorities – in addition to delivering customer satisfaction – is scaffolding safety. Once scaffolding goes up, it is not just a set-it-and-forget-it addition to the job site. So, how can you effectively protect your crew on your next job?

1. Use High-Quality, Properly Installed Equipment

Of the workers injured in scaffold-related accidents, 72 percent attributed the incident

to either the planking, support giving way, or to the employee slipping or being struck by a falling object.

What does that tell us? Well, for starters it indicates that the scaffolding in use may not be properly designed and deployed. A poorly designed scaffolding system can have disastrous consequences. If your job requires non-slick surfaces or special materials, any missing component could mean injury or worse for your team members.

Train your employees to recognize deficient, noncompliant and/or damaged structures, including missing essential safety components like Toeboards, Planks, or Guardrails. Also, consider working with a scaffolding manufacturer that provides application engineering to ensure you have the correct equipment for your project requirements.

2. Ensure Proper Training

A key scaffolding safety issue is whether or not the scaffold has been erected by trained professionals. Erection and dismantling must be done by competent persons to ensure a solid work space for overhead workers and a solid foundation to keep the scaffold stable.

In addition to being trained and up to date on OSHA requirements, all workers must be properly trained on setup, construction of scaffolding, how to handle materials and load capacities. Proper training should also be given on the type of scaffolding they are working on and the complexity of the scaffold being erected or dismantled.

3. Keep the Site Clean and Organized

You have likely heard the saying, “A clean job site is a safe job site. Still, “Housekeeping” is one of the most cited OSHA safety infractions. People who tend to leave a mess have a higher chance of tripping over equipment or slipping over messy work areas and causing accidents. Make sure all workers follow standard procedures to secure the job site before leaving for the day. This might include dewatering, removing debris, and ensuring all equipment is properly and securely stored.

4. Keep Your FLRA Updated

Refer back to your field level risk assessment (FLRA) on a periodic basis to identify hazards that may not have been previously documented. Review processes for material handling, power lines, inclement weather, and load-carrying capacity to keep these potential hazards top of mind and add to the list when needed. As workers get accustomed to a job site, they are less likely to be on alert to potential safety issues. A regular review of your FLRA can help prevent oversight and avoid simple mistakes that could affect job site safety.

No matter where you are or what job you are on, safety is nonnegotiable. If you need scaffolding that you can trust to get the job done while protecting the safety of your workers, please contact us

online today or call the branch office closest to you. We’ll begin the process of finding a scaffolding solution that meets your unique needs.

You might also like

AT-PAC Blog

By Julio Black

•

April 3, 2025

We are excited to share an important milestone in our journey. AT-PAC is now officially operating under umdasch Industrial Solutions. This transition further strengthens our position as an end-to-end scaffolding provider, expanding our reach and enhancing our ability to serve i ndustrial customers and scaffolding contractors worldwide.

By Julio Black

•

February 17, 2025

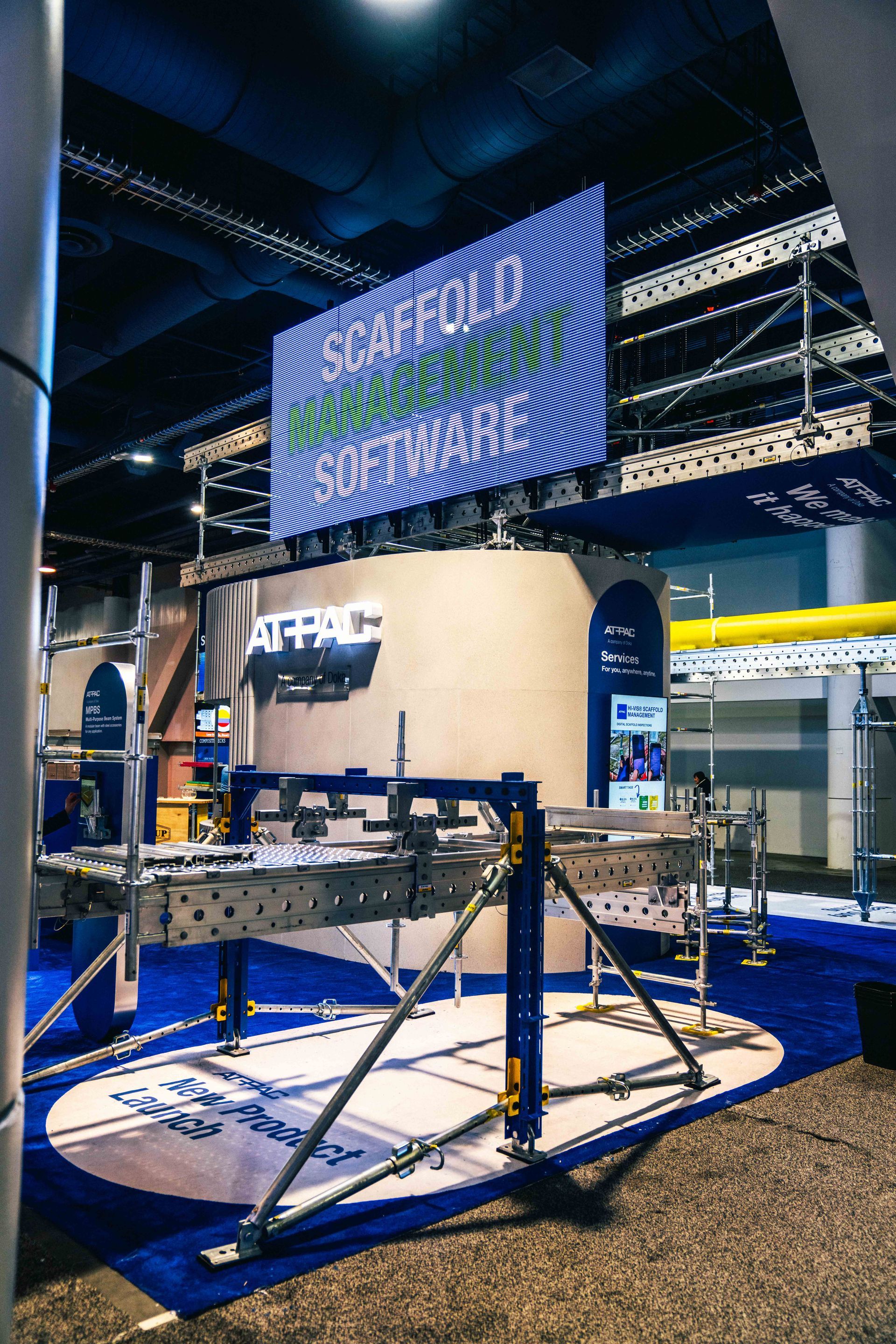

AT-PAC Unveils the Multi-Purpose Beam System (MPBS) at World of Concrete 2024 AT-PAC proudly launched its latest innovation, the Multi-Purpose Beam System (MPBS), at World of Concrete 2024, marking a significant milestone in scaffold technology. As a cutting-edge addition to AT-PAC’s proprietary Ringlock System Scaffold, the MPBS offers unparalleled versatility and efficiency, revolutionizing the way scaffold structures are designed and deployed. A Game-Changer for the Industry Designed to expand the capabilities of the Ringlock System, the MPBS provides a groundbreaking solution for a wide range of applications, including: Suspended Scaffold & Pipe Rack Scaffolds – Enabling safe and efficient suspended access solutions. Birdcages – Creating stable, large-scale work platforms. Large Span Bridging – Allowing for expansive scaffold spans with fewer components. Boiler Scaffolds – Meeting the unique needs of confined and high-heat environments. Cantilevers – Offering extended reach and accessibility. Innovative Design & Seamless Integration The MPBS system is engineered for simplicity and adaptability. At its core is a robust extruded aluminum beam, capable of supporting O-Type Ringlock Planks and an array of attachable steel accessories. With 6-inch (152.4mm) on-center attachment points along its length, the MPBS ensures maximum flexibility, making it suitable for diverse scaffolding applications. What sets the MPBS apart is its seamless integration into the Ringlock System, enhancing functionality while minimizing complexity. The ability to achieve larger spans than traditional methods reduces the overall number of components required, streamlining both installation time and labor costs.

About AT-PAC

Locations

Careers

GLOBAL HQ

Atlantic Pacific Equipment LLC (AT-PAC).

1455 Old Alabama Road Ste. 100

Roswell, GA 30076 USA

Scaffolding Solutions

Service

A company of umdasch Industrial Solutions

DISCLAIMER: The information contained in this website is provided by Atlantic Pacific Equipment, LLC (“AT-PAC”) and is for general information purposes only.

© 2025

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved

© 2025

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved