9 ESSENTIAL QUESTIONS TO ASK BEFORE CHOOSING A SCAFFOLDING MANUFACTURER

July 10, 2019

This is a subtitle for your new post

Each construction project comes with unique circumstances, but two elements underlie the success of every job site: time and money. The scaffolding manufacturer

you choose should understand the need to complete a project on time and on budget and work with you to make that happen.

Of course, no two scaffolding companies are exactly alike. It is important to choose one that is cost effective, provides high quality, and has sufficient inventory to meet your project needs.

For example, if you are up against a tight deadline, your scaffolding manufacturer should be able to quickly get you the proper equipment. You do not want to run into a situation of needing to reorder supplies and have them tell you it will take 3 weeks. By then, you will be behind schedule and left scrambling to make your deadline, juggle workload, and stay within budget.

Before you sign on the dotted line with a scaffolding manufacturer, make sure to ask these 9 questions:

- What is your available inventory?

- What is your prior experience?

- What is your volume purchasing offer(s) or discounts for your customers?

- What is the normal delivery time from your manufacturing or production facilities to your customers?

- What is the delivery (freight) cost per load for your equipment?

- Do you offer design and technical support services with purchase and rental equipment?

- Is your equipment inter-mixable with other suppliers who produce the same type of gear as you?

- Do you offer any type of buy-back deals after a project is completed?

- Do you provide any post-sale customer service?

As a next step, you have to discuss PRICE. Certainly, the final cost of the scaffolding solution you choose is important. Anyone who tries to claim otherwise does not understand budgeting requirements.

However, it is important to note that price should never be the only deciding factor. In fact, it should not even be the highest priority.

An experienced scaffolding solutions partner who consistently produces a high-quality product and extensive support may very well charge slightly more than a less experienced provider who is more concerned with closing the sale and moving on. At the same time, your scaffolding manufacturer should talk with you about potential discounts to help you meet your project budget.

If the overall cost is reasonable and value is added through product quality and customer support, the additional cost will be a worthwhile investment.

When you are ready to move forward with confidence, call our closest regional office or contact us

online.

You might also like

AT-PAC Blog

We are excited to share an important milestone in our journey. AT-PAC is now officially operating under umdasch Industrial Solutions. This transition further strengthens our position as an end-to-end scaffolding provider, expanding our reach and enhancing our ability to serve i ndustrial customers and scaffolding contractors worldwide.

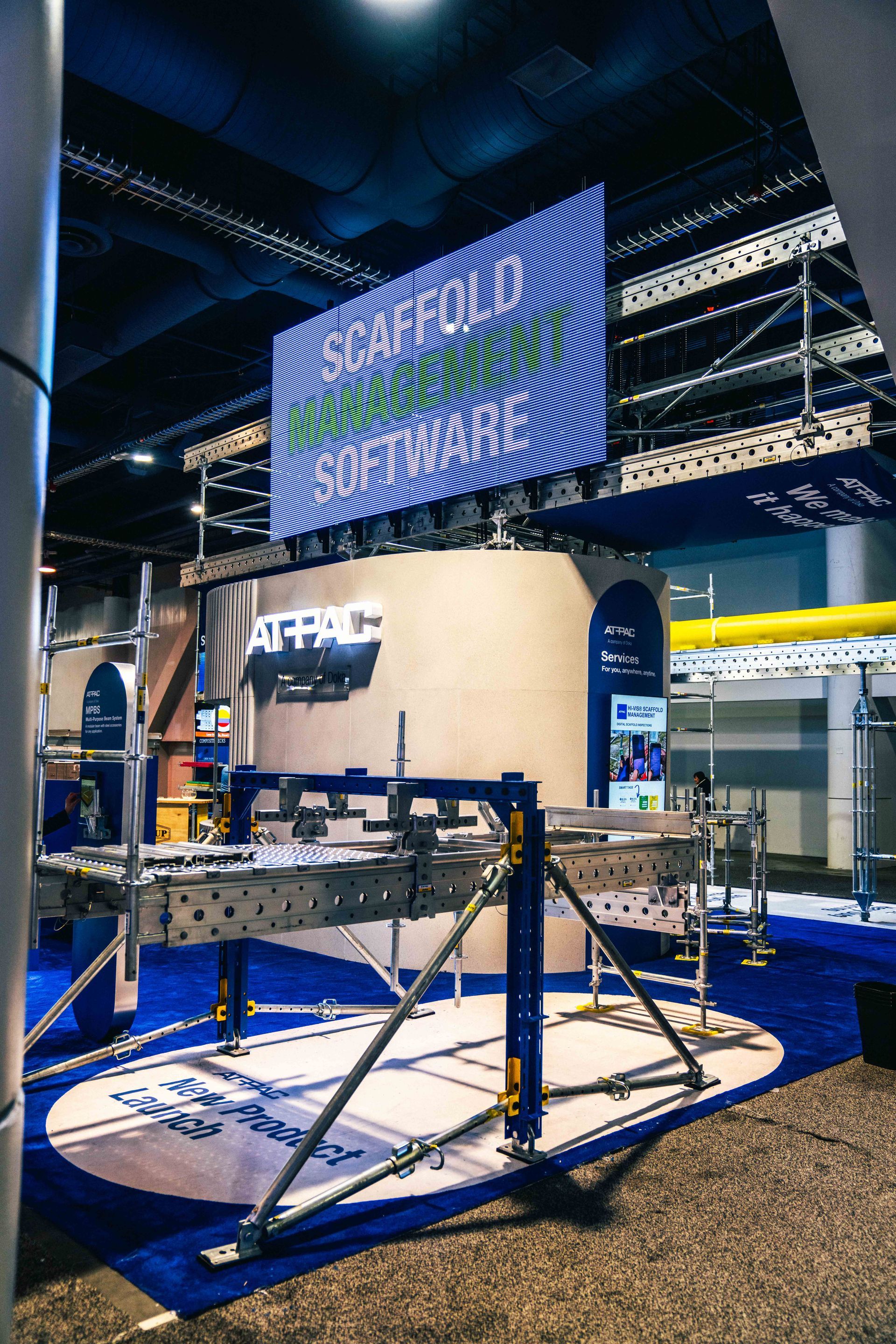

AT-PAC Unveils the Multi-Purpose Beam System (MPBS) at World of Concrete 2024 AT-PAC proudly launched its latest innovation, the Multi-Purpose Beam System (MPBS), at World of Concrete 2024, marking a significant milestone in scaffold technology. As a cutting-edge addition to AT-PAC’s proprietary Ringlock System Scaffold, the MPBS offers unparalleled versatility and efficiency, revolutionizing the way scaffold structures are designed and deployed. A Game-Changer for the Industry Designed to expand the capabilities of the Ringlock System, the MPBS provides a groundbreaking solution for a wide range of applications, including: Suspended Scaffold & Pipe Rack Scaffolds – Enabling safe and efficient suspended access solutions. Birdcages – Creating stable, large-scale work platforms. Large Span Bridging – Allowing for expansive scaffold spans with fewer components. Boiler Scaffolds – Meeting the unique needs of confined and high-heat environments. Cantilevers – Offering extended reach and accessibility. Innovative Design & Seamless Integration The MPBS system is engineered for simplicity and adaptability. At its core is a robust extruded aluminum beam, capable of supporting O-Type Ringlock Planks and an array of attachable steel accessories. With 6-inch (152.4mm) on-center attachment points along its length, the MPBS ensures maximum flexibility, making it suitable for diverse scaffolding applications. What sets the MPBS apart is its seamless integration into the Ringlock System, enhancing functionality while minimizing complexity. The ability to achieve larger spans than traditional methods reduces the overall number of components required, streamlining both installation time and labor costs.