SCAFFOLDING SAFETY: HOW TO USE SCAFFOLDING FOR PROTECTION IN EXTREME COLD WEATHER

July 11, 2019

Cold weather can wreak havoc on a job site. Paint will not dry properly and materials and surfaces are unable to reach the required temperatures for proofing and preparation. In addition, limitations of the human body mean your team simply cannot function at the highest level in below freezing temperatures.

Fortunately, scaffolding containment helps protect your job site and workers from extreme cold so you can maintain optimal levels of performance and complete the job on time. Here is a closer look at how to ensure scaffolding safety

in extremely cold weather.

Scaffolding Containment

Scaffolding safety starts with containment, which protects your job site using material that surrounds the scaffolding structure. This material is also known as hoarding. Common types of hoarding include plywood and tarp.

The application process starts by laying the hoarding material you select across the scaffold. Then, a fire blanket or other fire-retardant material is placed on the floor on top of the hoarding material. All materials should be bound tightly to form an adequate seal.

When you use an enclosure it puts extra wind loads into the structure and it could lift up like a huge sail. Therefore, special design is required when sheeting is used on the outside of scaffolding. Butts, ties, and diagonals

are required every other lift vertically.

Elements to Consider

Sufficient access and egress

are critical elements to hoarding design. Make sure there is enough room for uninhibited movement to and from the hoarding, while maintaining sufficient containment.

Quality designs include a “Weather Strip” that provides an overlap to keep it sealed up tight. Typically, a secondary containment room and an adjacent changing room are also incorporated in the design when hazardous containment applications are needed. Components such as the Ten Leg Steel Stair, Aluminum Platform Stair, and Vertical Ladder

can all be used to create a secondary containment room.

1. Roof Support

Another critical element to a hoarding design is an adequately designed and framed roof. A roof helps support the buildup of water, ice, and snow. It also protects against environmental hazards such as waste, dirt, and rust, or any overhead hazard that could fall or be placed on the hoarding roof.

2. Adequate Ventilation

Adequate ventilation within the hoarding should remain a top priority for scaffolding safety. Continuously monitor the hoarding atmosphere based on the standards from the Occupational Safety and Health Administration, or the Occupational Health & Safety Codes of Canada. Typically, this monitoring includes but is not limited to:

- Oxygen (O2)

- Lower Explosive Limit (LEL)

- Carbon Monoxide (CO)

- Thermal/Smoke and Hydrogen Sulphide (H2S)

Cold weather doesn’t have to result in the shutdown of your job site. Taking a few extra steps and precautions can keep your site safe, your team working efficiently, and your project on track.

If you’re losing project time to cold weather, the scaffolding product design

specialists at AT-PAC can help. Contact us and we can help you design a perfect custom solution to meet all of your project’s needs.

You might also like

AT-PAC Blog

We are excited to share an important milestone in our journey. AT-PAC is now officially operating under umdasch Industrial Solutions. This transition further strengthens our position as an end-to-end scaffolding provider, expanding our reach and enhancing our ability to serve i ndustrial customers and scaffolding contractors worldwide.

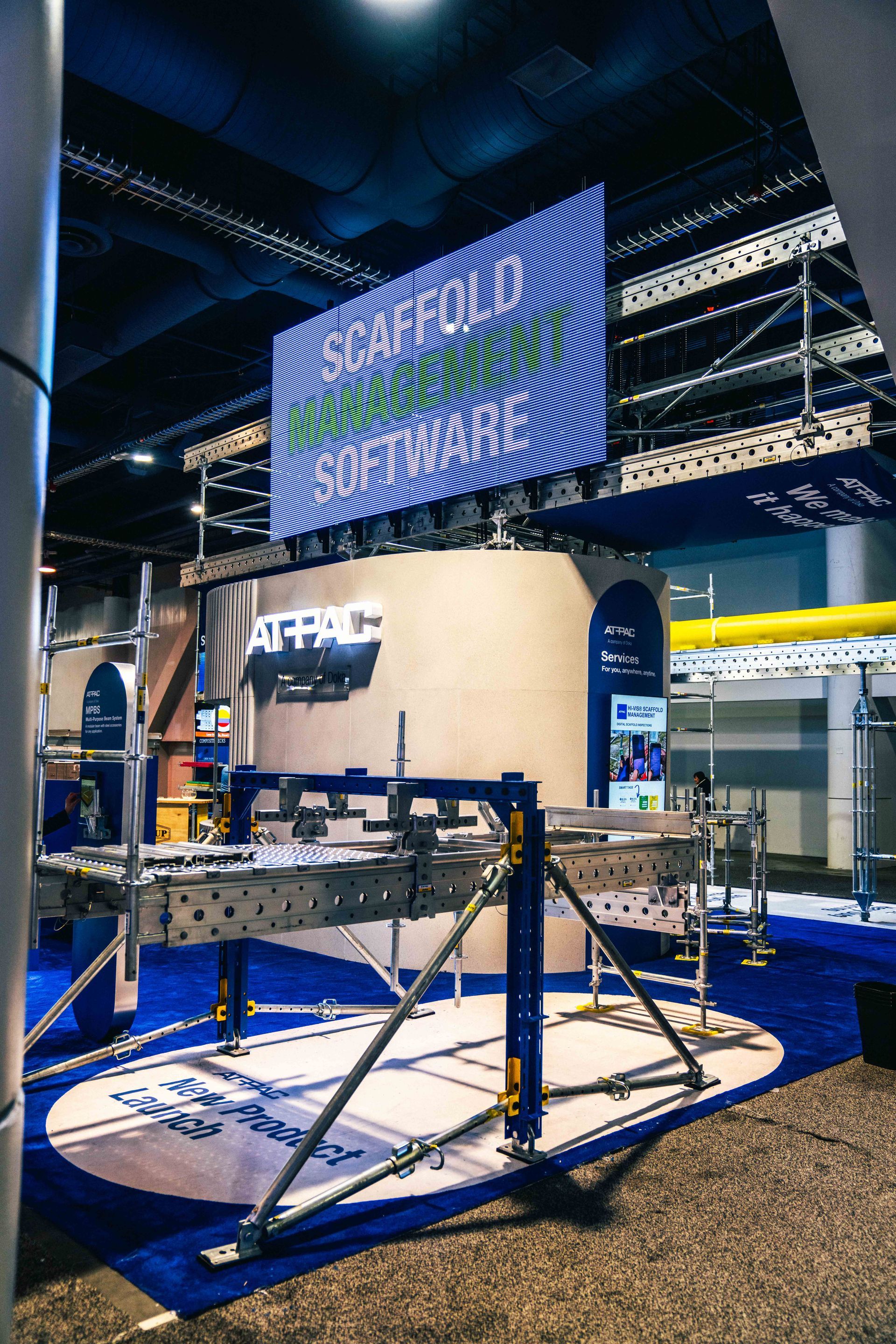

AT-PAC Unveils the Multi-Purpose Beam System (MPBS) at World of Concrete 2024 AT-PAC proudly launched its latest innovation, the Multi-Purpose Beam System (MPBS), at World of Concrete 2024, marking a significant milestone in scaffold technology. As a cutting-edge addition to AT-PAC’s proprietary Ringlock System Scaffold, the MPBS offers unparalleled versatility and efficiency, revolutionizing the way scaffold structures are designed and deployed. A Game-Changer for the Industry Designed to expand the capabilities of the Ringlock System, the MPBS provides a groundbreaking solution for a wide range of applications, including: Suspended Scaffold & Pipe Rack Scaffolds – Enabling safe and efficient suspended access solutions. Birdcages – Creating stable, large-scale work platforms. Large Span Bridging – Allowing for expansive scaffold spans with fewer components. Boiler Scaffolds – Meeting the unique needs of confined and high-heat environments. Cantilevers – Offering extended reach and accessibility. Innovative Design & Seamless Integration The MPBS system is engineered for simplicity and adaptability. At its core is a robust extruded aluminum beam, capable of supporting O-Type Ringlock Planks and an array of attachable steel accessories. With 6-inch (152.4mm) on-center attachment points along its length, the MPBS ensures maximum flexibility, making it suitable for diverse scaffolding applications. What sets the MPBS apart is its seamless integration into the Ringlock System, enhancing functionality while minimizing complexity. The ability to achieve larger spans than traditional methods reduces the overall number of components required, streamlining both installation time and labor costs.