Blog Layout

HOW CUSTOM SCAFFOLDING ENGINEERING POWERS A PROFITABLE EPC PROJECT

July 9, 2019

Scaffolding engineering

services allow you to tailor parts to fit your unique needs. Here is a strange question, but answer it honestly:

Have you ever purchased a garment labeled “one-size-fits-all” that you truly loved? Did you get plenty of gushing compliments on how well it suited you? Were you loath to give it up when it was so worn out from use that you could not possibly wear it anymore?

The answer is no. Guaranteed. And there is good reason for that.

“One-size-fits-all” products and services are inferior to custom-designed, tailored solutions, whether you are talking about clothing, medical care, or scaffolding.

The last thing an Engineering Procurement Construction (EPC) contractor with complex projects should rely on is a one-size-fits-all scaffolding solution. No two job sites are exactly alike. Every project is completely unique with a host of individual features and challenges. Trying to retrofit general scaffolding equipment to an EPC project is not only frustrating, but can ultimately cost more in the end.

Scaffolding engineering services provide optimal solutions for projects with unique requirements. Scaffolding engineering services typically include a consultation to determine project scope, 2d & 3d layout drawings based on customer requirements, PE stamped drawings and calculations (as required), material takeoff, and product manuals and user guides including technical manuals.

How Scaffolding Engineering Services Deliver Positive ROI for EPC Contractors

1. Reduces the chances for change

Trying to retrofit a general use scaffolding set-up to your unique EPC project typically results in complications like having to alter materials and purchase additional modules. reduces the chance of having to go back to your scaffolding supplier for new parts and pieces along the way. is always appreciated.

2. Streamlines the process to stay within budget

It is much more challenging to retrofit a scaffolding system with custom accessories than ordering all of the pieces and parts needed from the start. A custom approach enables you to get scaffolding up and working quickly to eliminate wasted time, resources and, money.

What to Look for in a Successful Scaffolding Design Process

Of course, achieving an optimal EPC project arrangement through custom scaffolding design is not an overnight process. The first key is partnering with the right scaffolding manufacturer, and the second is ensuring they are involved from the initial planning stages of the project so that a solution can be both time- and cost-effective from the start.

The best scaffolding engineering processes follow this basic outline:

- Consultation

- Design a customized solution

- Provide initial 2d & 3d designs for review

- Modify designs based on review

- Submit drawings, calculations & material takeoff for project

If you would like to discuss how AT-PAC’s industrial scaffolding solutions

can make your next EPC project easier and more profitable,

please call the AT-PAC regional office closest to you or contact us online.

You might also like

AT-PAC Blog

By Julio Black

•

April 3, 2025

We are excited to share an important milestone in our journey. AT-PAC is now officially operating under umdasch Industrial Solutions. This transition further strengthens our position as an end-to-end scaffolding provider, expanding our reach and enhancing our ability to serve i ndustrial customers and scaffolding contractors worldwide.

By Julio Black

•

February 17, 2025

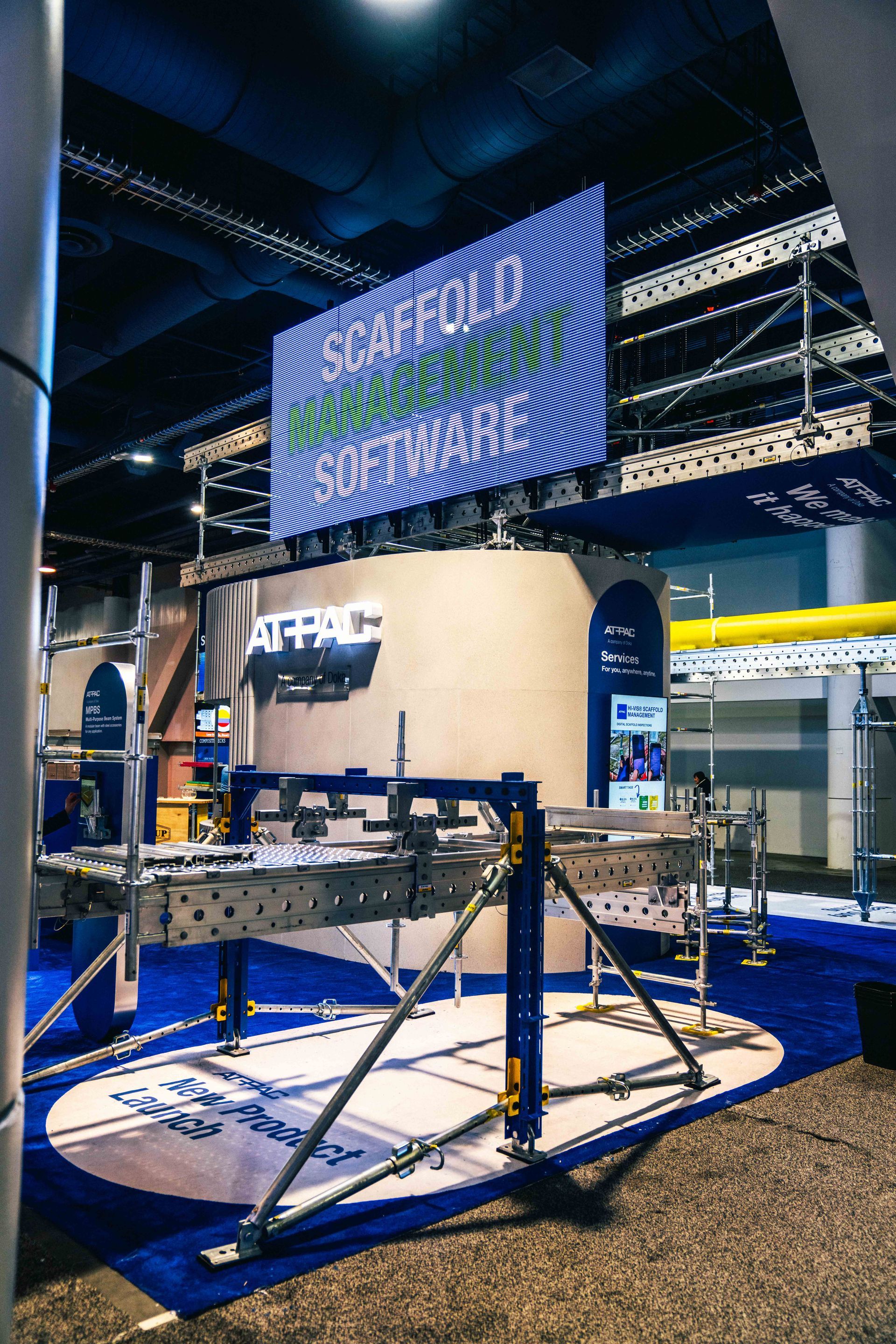

AT-PAC Unveils the Multi-Purpose Beam System (MPBS) at World of Concrete 2024 AT-PAC proudly launched its latest innovation, the Multi-Purpose Beam System (MPBS), at World of Concrete 2024, marking a significant milestone in scaffold technology. As a cutting-edge addition to AT-PAC’s proprietary Ringlock System Scaffold, the MPBS offers unparalleled versatility and efficiency, revolutionizing the way scaffold structures are designed and deployed. A Game-Changer for the Industry Designed to expand the capabilities of the Ringlock System, the MPBS provides a groundbreaking solution for a wide range of applications, including: Suspended Scaffold & Pipe Rack Scaffolds – Enabling safe and efficient suspended access solutions. Birdcages – Creating stable, large-scale work platforms. Large Span Bridging – Allowing for expansive scaffold spans with fewer components. Boiler Scaffolds – Meeting the unique needs of confined and high-heat environments. Cantilevers – Offering extended reach and accessibility. Innovative Design & Seamless Integration The MPBS system is engineered for simplicity and adaptability. At its core is a robust extruded aluminum beam, capable of supporting O-Type Ringlock Planks and an array of attachable steel accessories. With 6-inch (152.4mm) on-center attachment points along its length, the MPBS ensures maximum flexibility, making it suitable for diverse scaffolding applications. What sets the MPBS apart is its seamless integration into the Ringlock System, enhancing functionality while minimizing complexity. The ability to achieve larger spans than traditional methods reduces the overall number of components required, streamlining both installation time and labor costs.

About AT-PAC

Locations

Careers

GLOBAL HQ

Atlantic Pacific Equipment LLC (AT-PAC).

1455 Old Alabama Road Ste. 100

Roswell, GA 30076 USA

Scaffolding Solutions

Service

A company of umdasch Industrial Solutions

DISCLAIMER: The information contained in this website is provided by Atlantic Pacific Equipment, LLC (“AT-PAC”) and is for general information purposes only.

© 2025

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved

© 2025

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved