THE IMPORTANCE OF 3D MODELING WHEN DETERMINING YOUR SCAFFOLDING SYSTEM NEEDS

July 12, 2019

Three-dimensional (3D) modeling has transformed a number of industries. It is used in medicine, filmmaking, interior design, and architecture to name a few. It is also used with great effect to help determine scaffolding system needs.

Using specialized software, 3D modeling develops a graphical model of a surface of an object. The model is often displayed as a two-dimensional image, but it can also be created in three dimensions using 3D printing.

Computer graphics technology first emerged in the 1960s, but it was not until the 1970s that 3D modeling software became commercially available. Today, the market for 3D content continues to thrive through marketplaces like Turbosquid and CGTrader.

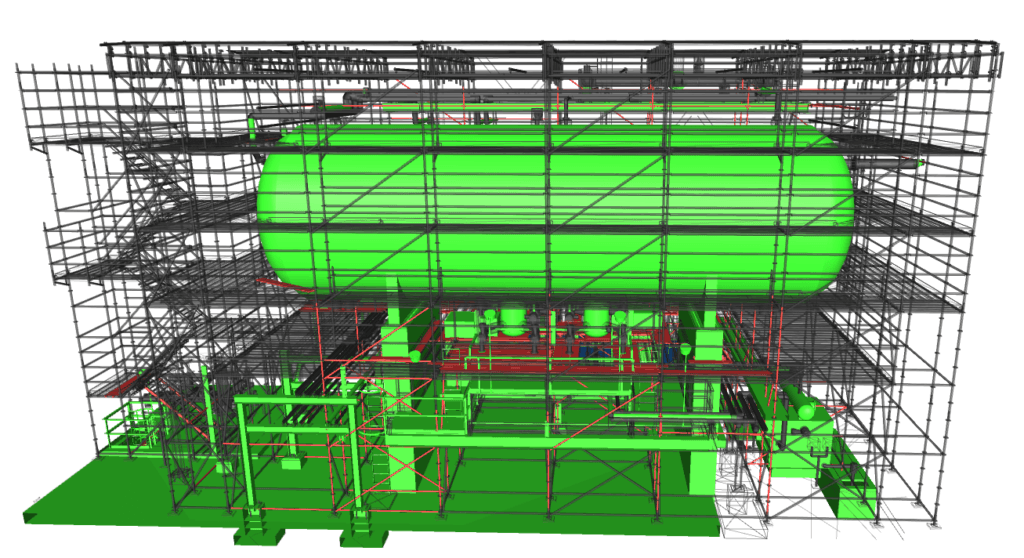

In the construction and industrial sectors, engineers use 3D modeling to help determine their scaffolding system

needs and often include 3D renderings in reports and proposals. Let’s take a closer look at how 3D modeling is used to determine scaffolding requirements.

Using 3D Modeling to Determine Materials and Estimate Costs

Many contractors and engineers use 3D modeling to help them navigate the scaffolding system selection process more efficiently. This technology helps:

- Create materials lists

- Create quotes and estimates

- Visualize scaffolding structures

- Save on engineer’s fees

Using 3D modeling ensures scaffolding structures are compliant before they are ever constructed. Additionally, the technology can be used to analyze existing structures to identify noncompliant areas and inefficiencies

Scaffolding design software

Application engineers use the most advanced industry design software to develop scaffold designs

and material lists, including:

- AutoCAD 2D & 3D

- Navisworks for building information modeling

- Solidworks for product design and animations

- Scaffold Designer for unique, customizable components, to build materials lists and calculate leg loads while building plans. It also integrates with AutoCAD

- Smart Scaffolder to import 2D CAD files and plans and create 3D project estimates and quotes. Smart Scaffolder also ensures your plans are in compliance with TG20:13 criteria

These technologies help create a realistic representation of your scaffold. The 3D-modeling process can be particularly advantageous when working on unique structures that require abnormal scaffolding solutions.

AT-PAC custom engineers scaffolding solutions

that meet the parameters of even the most unique projects. Contact us if you want to explore the creation of a scaffolding system that fits all of your projects needs, or call the regional office closest to you. We will discuss the challenges you face and find a solution that works.

You might also like

AT-PAC Blog

We are excited to share an important milestone in our journey. AT-PAC is now officially operating under umdasch Industrial Solutions. This transition further strengthens our position as an end-to-end scaffolding provider, expanding our reach and enhancing our ability to serve i ndustrial customers and scaffolding contractors worldwide.

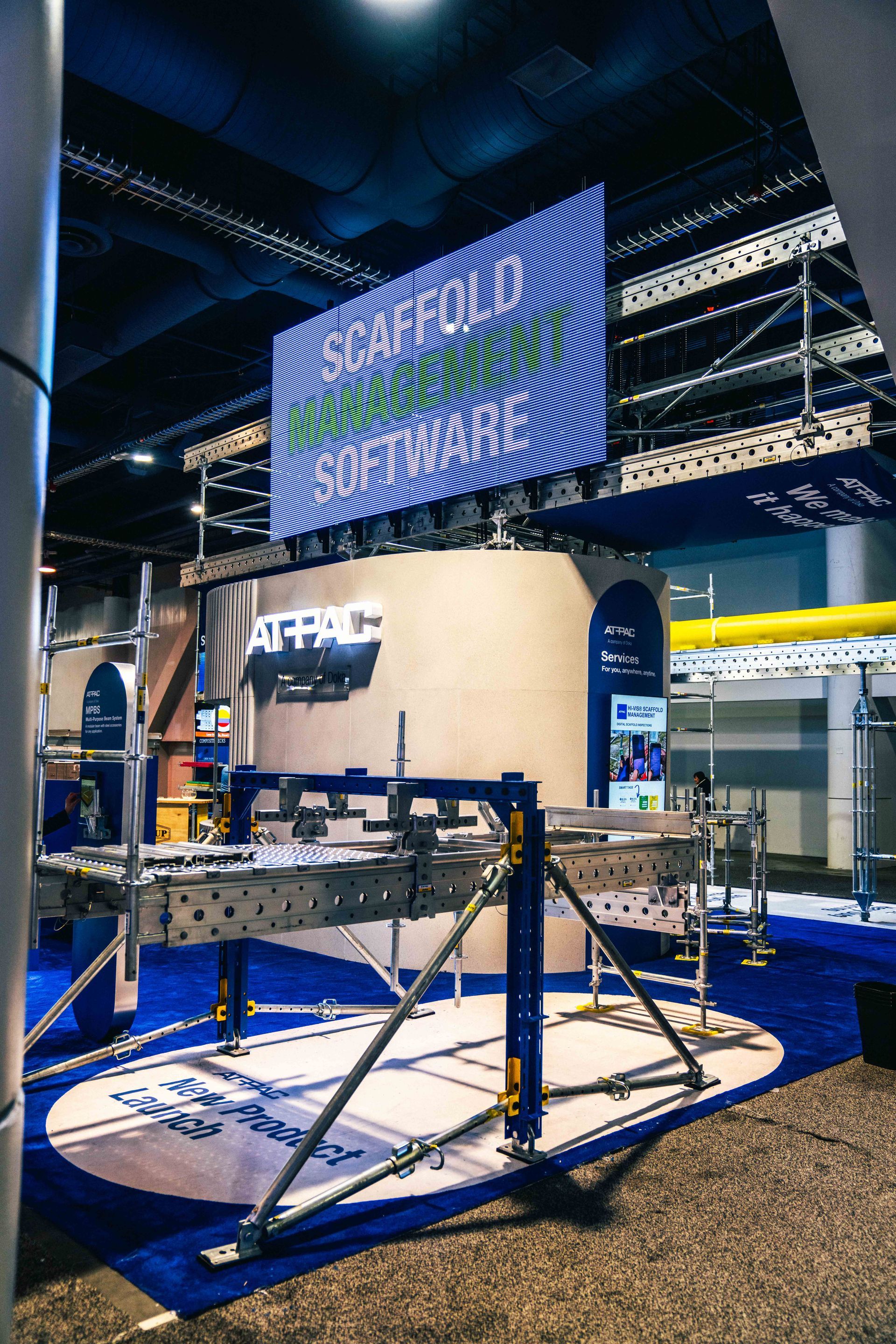

AT-PAC Unveils the Multi-Purpose Beam System (MPBS) at World of Concrete 2024 AT-PAC proudly launched its latest innovation, the Multi-Purpose Beam System (MPBS), at World of Concrete 2024, marking a significant milestone in scaffold technology. As a cutting-edge addition to AT-PAC’s proprietary Ringlock System Scaffold, the MPBS offers unparalleled versatility and efficiency, revolutionizing the way scaffold structures are designed and deployed. A Game-Changer for the Industry Designed to expand the capabilities of the Ringlock System, the MPBS provides a groundbreaking solution for a wide range of applications, including: Suspended Scaffold & Pipe Rack Scaffolds – Enabling safe and efficient suspended access solutions. Birdcages – Creating stable, large-scale work platforms. Large Span Bridging – Allowing for expansive scaffold spans with fewer components. Boiler Scaffolds – Meeting the unique needs of confined and high-heat environments. Cantilevers – Offering extended reach and accessibility. Innovative Design & Seamless Integration The MPBS system is engineered for simplicity and adaptability. At its core is a robust extruded aluminum beam, capable of supporting O-Type Ringlock Planks and an array of attachable steel accessories. With 6-inch (152.4mm) on-center attachment points along its length, the MPBS ensures maximum flexibility, making it suitable for diverse scaffolding applications. What sets the MPBS apart is its seamless integration into the Ringlock System, enhancing functionality while minimizing complexity. The ability to achieve larger spans than traditional methods reduces the overall number of components required, streamlining both installation time and labor costs.