SCAFFOLDING ACCESSORIES FOR UNUSUAL STRUCTURES

July 11, 2019

When the layperson thinks about scaffolding, they think about straightforward applications on the regular facades of multi-story buildings. Many scaffolding applications do resemble what the public sees every day.

However, unique scaffolding structures are needed at specialized job sites, like shipbuilding yards, chemical plants, and industrial sites where complex job conditions demand specific accessories. The average scaffolding will not cut it on the side of an oil tanker or inside the chimney of a refinery.

Luckily, modern scaffolding equipment is adaptable. Scaffolding accessories help numerous professionals handle the rigors of work on unusual structures.

Industries leveraging scaffolding accessories

It would be great if every job site you worked on was straightforward and did not require any additional tools or resources. The reality is a bit different. Certain industry professionals require unique scaffolding applications to make their jobs easier, as in these examples:

- Shipbuilders cannot build a scaffold on the ocean. Instead, they erect suspended scaffolding, which is supported from the top down and brace back to the ship.

- Carpenters and masons commonly use frame-and-brace scaffolding on commercial jobs because it requires less components and is easier to setup.

- Industrial contractors apply a “hooch” on job sites. The hooch is a makeshift house covered in tarp used to protect parts and equipment on industrial sites.

- Sandblasters commonly employ five-by-seven-foot bays placed at least eight inches to one foot away from the wall they work on to avoid sandblast and pelts hitting them.

The right tools for the job

If you encounter unusual structures or unique situations at your job site, there are a number of scaffolding accessories that can help you and your crew execute more efficiently. Here are a few examples:

- Corner Planks allow you to create closed gaps within a circular scaffold and without the need for additional tube-and-clamp, saving you time and money on labor.

- The Horizontal Rosette Clamp allows you to add a ledger anywhere along the length of a ringlock bay. This is an improvement on the mid-transom because it lets you utilize regular ringlock ledgers as opposed to multiple lengths of mid-transoms.

- The Infill Plank is a great tool for closing gaps in platforms. Designed to sit on top of the Ringlock ledger and rest on two ringlock planks on either side, it creates a seamless working platform.

- The Davit Arm is a good tool for fall protection. It is used to secure a retractable lifeline designed specifically for climbing vertical ladders or most commonly it is used to lift components up and down a scaffold with a Gin Wheel.

AT-PAC’s Ringlock scaffolding system can be adapted with any one of these accessories to fit any number of unique and unusual job sites. Our industrial scaffolding solutions meet or exceed the highest American and European safety and durability standards. For more information about the best scaffolding accessories for your job site, call our closest regional office or contact us

online.

You might also like

AT-PAC Blog

We are excited to share an important milestone in our journey. AT-PAC is now officially operating under umdasch Industrial Solutions. This transition further strengthens our position as an end-to-end scaffolding provider, expanding our reach and enhancing our ability to serve i ndustrial customers and scaffolding contractors worldwide.

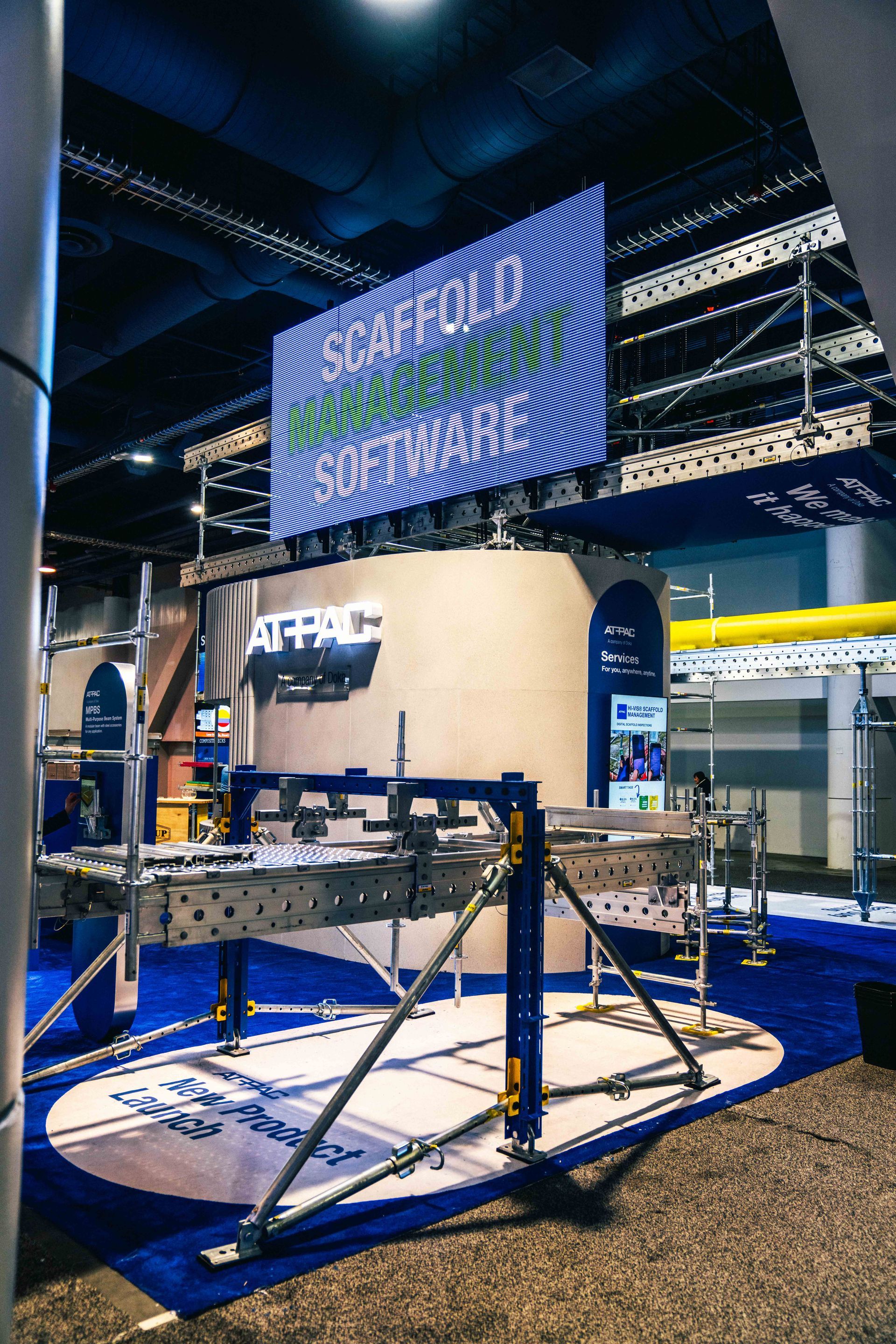

AT-PAC Unveils the Multi-Purpose Beam System (MPBS) at World of Concrete 2024 AT-PAC proudly launched its latest innovation, the Multi-Purpose Beam System (MPBS), at World of Concrete 2024, marking a significant milestone in scaffold technology. As a cutting-edge addition to AT-PAC’s proprietary Ringlock System Scaffold, the MPBS offers unparalleled versatility and efficiency, revolutionizing the way scaffold structures are designed and deployed. A Game-Changer for the Industry Designed to expand the capabilities of the Ringlock System, the MPBS provides a groundbreaking solution for a wide range of applications, including: Suspended Scaffold & Pipe Rack Scaffolds – Enabling safe and efficient suspended access solutions. Birdcages – Creating stable, large-scale work platforms. Large Span Bridging – Allowing for expansive scaffold spans with fewer components. Boiler Scaffolds – Meeting the unique needs of confined and high-heat environments. Cantilevers – Offering extended reach and accessibility. Innovative Design & Seamless Integration The MPBS system is engineered for simplicity and adaptability. At its core is a robust extruded aluminum beam, capable of supporting O-Type Ringlock Planks and an array of attachable steel accessories. With 6-inch (152.4mm) on-center attachment points along its length, the MPBS ensures maximum flexibility, making it suitable for diverse scaffolding applications. What sets the MPBS apart is its seamless integration into the Ringlock System, enhancing functionality while minimizing complexity. The ability to achieve larger spans than traditional methods reduces the overall number of components required, streamlining both installation time and labor costs.